- CONTACT EMAIL:

- sales@signialuminium.com

Now, the edge trims are mainly divided into metal edge trims and PVC edge trims. According to the material, the metal edge trim can be divided into three categories: aluminum, copper, and stainless steel. For different materials, corresponding construction operations need to be carried out during the construction stage.

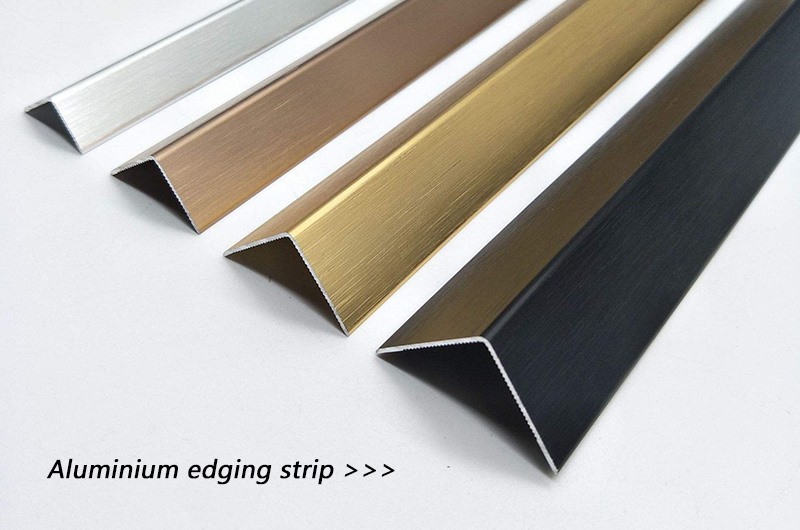

This time we will mainly introduce aluminum edging strip.

The aluminium edging strip is made by extruding pure aluminum with alloying elements such as manganese and magnesium. It has the characteristics of light weight, corrosion resistance and wear resistance. Its surface has a bright metallic luster after anodizing and coloring treatment, which is light and weather resistant. However, pay special attention to these 5 matters during construction:

1. Inspection and confirmation before construction

Before the construction of the aluminium edging strip, check its surface for scratches, deformation, etc., and confirm whether the color, size, and specifications of the edge strip match the on-site requirements, and start construction after all confirmations are correct.

2. Prevent corrosion of acid and alkali substances

Metal materials will be corroded, as is the aluminum edging strip.

Nowadays, there are many tile glues and grouts on the market that contain relatively high alkaline substances. After this type of tile glue and grout are mixed with water, they will adhere to the surface of the edge trim, which will have a corrosive effect on the electroplating layer. After a long time of chemical reaction, the electroplating layer on the surface of the edge trim will slowly appear crystalline material, which cannot be cleaned. The post-remediation can only be polished and re-sprayed on the surface. In serious cases, the edge trim can only be removed and re-applied. Installation increases the construction cost and delays the construction period.

3. Remove the film after construction

Imported brand edge trim products have film packaging on the surface. This film can be removed after construction. This not only protects the electroplating layer from scratches, but also prevents corrosion by corrosives and reduces the probability of oxidation.

4. Avoid using alkaline cleaning products during maintenance

During construction, if there are stains remaining on the surface of the material, it should be cleaned with clean water in time. In the later cleaning and maintenance process, pay special attention to not using strong alkaline cleaning products such as decontamination powder, which will damage the electroplated layer on the surface of the edge trim.

5. The choice of ground edge trim

Aluminium edging strip is mostly used on walls. When used on the ground, try to choose the original color of aluminum to prevent hard objects from scratching the electroplated layer.

Aluminium edging strip, because of the diversity of colors, patterns, styles, specifications, etc., has very high plasticity and can be widely used in various places. Because it is made of metal, certain professional knowledge is required for installation and maintenance during and after construction. Once the wrong construction tools or construction materials are selected, it will cause irreparable losses to the edge trim.

Mobile:86 17344894490

Email:sales@signialuminium.com

Address:A126 Building 4, No.89 Science Avenue,National HI-Tech Industry Development Zone,Zhengzhou,Henan