- CONTACT EMAIL:

- sales@signialuminium.com

1 Project overview

Guangxi Culture and Art Center is located on the bank of the Yongjiang River in Wuxiang New District, Nanning City, across the river from Qingxiu Mountain. Guangxi Culture and Art Center is a landmark project in Nanning. It is mainly composed of a 1,800-seat Grand Theater, a 1,200-seat concert hall, and a 600-seat multi-purpose hall. constitute. The steel structure of the project is mainly formed by 3 giant arch structures (Grand Theater, Concert Hall, Multi-Function Hall) connected to each other by a horizontally set plane cross truss system (cloud canopy), and a concrete structure with an elevation of 6.5 m is supported by hinges. On the other hand, the overall steel structure system is relatively independent. A large number of aluminum plates and grilles of various shapes are used as decorative layers in the vault, cloud canopy and façade. From a distance, the Grand Theater is rising like a white cloud, with a unique and eye-catching shape, becoming an important culture in Nanning and even Guangxi. business card (Figure 1).

This paper focuses on the aluminum plate system for wall and roof decoration, gives a brief introduction to the project's enclosure system from the design point of view, and analyzes the specific application of aluminum alloy materials in the project.

2 Design scheme

The roof shape of Guangxi Culture and Art Center is an irregular shape design. The waterproof part of the roof of the three main buildings is waterproof with concrete structure, and the geometric shape part is aluminum trim coil. aluminum trim coil mainly includes the following parts:

A. Lighting system of glass curtain wall between arches;

B. Arched outdoor profile aluminum trim coil;

C. Vaulted indoor pressure aluminum trim coil;

D. The aluminum alloy grille system of the roof of the vaulted room;

E. Canopy composite aluminum trim coil.

The specific location and arrangement of each decoration system are shown in Figure 2.

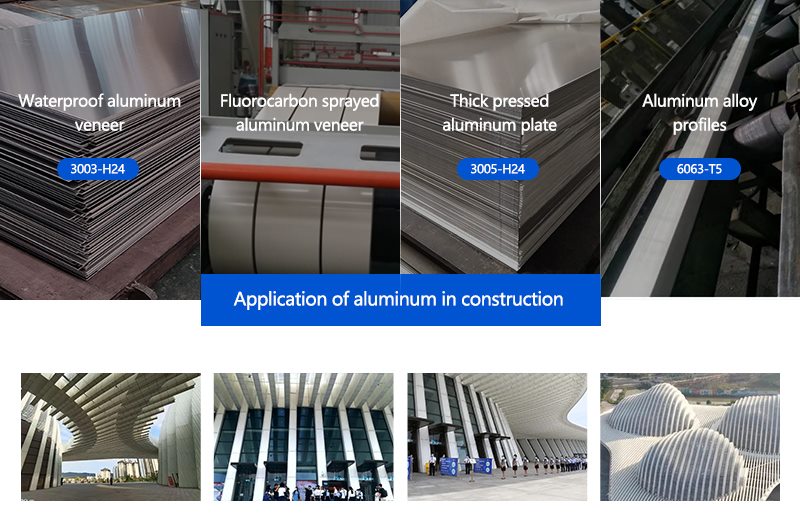

3 Construction of each system and materials used

3.1 Glass curtain wall system between arches

The glass curtain wall system between the arches is located below the cloud canopy, and is set in local locations. It consists of unitized glass curtain wall, fluorocarbon sprayed aluminum veneer, aluminum alloy ventilation shutters, openable fire rescue windows, and entrance doors. The main grid size of the curtain wall is 2 150 mm(W)×1 740 mm(H), and the glass panel mainly adopts 8+12A+8LOW-E+1.52PVB+8 ultra-white tempered hollow laminated glass and 8+12A+8LOW-E +1.52PVB+8 ultra-white tempered hollow laminated color glaze glass, the color glaze surface is located on the inner side of the hollow layer; the thickness of the fluorocarbon sprayed aluminum veneer is 3 mm.

3.2 Arched outdoor profile aluminum trim coil

The arched outdoor profile aluminum trim coil is divided into upper and lower parts. The building elevation is below 24 m. The outer panel is slotted. The inner layer has the functions of heat preservation, waterproofing, sound insulation and noise reduction. The closed circles of the system together form the facade envelope system of the building. The height of the building is above 24 m, and the overall opening method is adopted. Only the top end needs to have waterproof function, and other functions are not required; Aluminum veneer, 60 mm thick glass fiber insulation cotton, 1.5 mm thick galvanized bottom plate, etc.

The thickness of the profiled aluminum plate is 3 mm, and two cross-section plate types are staggered (see Figure 3), with a width of 1 m and a height of 3 m. Fluorocarbon paint treatment.

The 1.5 mm thick self-adhesive TPO waterproofing membrane has excellent properties of UV resistance, aging resistance and mildew resistance, and its durability is not less than 15 years. The waterproof aluminum veneer alloy grade is 3003, the state is H24, the thickness is 2.5mm, the surface is anodized, and the film thickness reaches the AA15 level.

3.3 Vaulted indoor profile aluminum trim coil

The vaulted indoor profile aluminum trim coil is a whole slotted method, which only has a decorative function. It is composed of 3 mm thick pressed aluminum plate, aluminum alloy profile, etc. The material, thickness and section of the pressed aluminum plate are consistent with the outdoor.

3.4 Aluminum alloy grille decoration system between arches

The aluminum alloy grille trim system between the arches is located between the two layers of the arch trim system. The aluminum alloy grille is composed of 140 mm×140mm aluminum square tubes with a spacing of 450 mm. Every 3 aluminum square tubes and aluminum alloy profiles form a grille unit, which is made by the factory and the unit is installed on site as a whole (see Figure 1). 4).

The grade of aluminum alloy profile is 6063-T5. The aluminum alloy profiles of the main force-bearing structure, including the columns and beams, are all high-precision extruded profiles, and the surface is treated with fluorocarbon spraying, and the average thickness of the coating is not less than 45μm.

3.5 Canopy composite aluminum trim coil

The canopy composite aluminum trim coil is located at 19.55 to 24.5 m, and the canopy cantilever truss, ring truss and outer ring rods are formed by 4 mm composite aluminum plates to form the decorative surface. The standard width of the composite aluminum plate is 1m, and there is no horizontal grid line in the height direction. The basic structure consists of composite aluminum plate, 1.5 mm thick self-adhesive TPO waterproof membrane, 2.5 mm thick waterproof aluminum veneer, curtain wall supporting members, aluminum alloy profiles, etc. The thickness of the front and back aluminum plates of the composite aluminum plate is not less than 0.5 mm, the aluminum alloy grade is 5005, the alloy state is H24, the thickness of the core material is 3 mm, and the primary particle low-density composite core material is used. The height direction is the entire length of the board. The fixed point of the composite aluminum plate is fixed on the secondary skeleton member with stainless steel self-tapping screws, and the exposed nail heads of the stainless steel self-tapping screws are sprayed with white coating to ensure the visual effect of the facade.

4 Waterproof treatment

4.1 Main roof waterproofing

The enclosure structure system of this project mainly plays the role of beautiful decoration and outstanding shape, but it does not have the function of waterproof and thermal insulation. performance (see Figure 5).

4.2 Outer gutter drainage

The top of the canopy adopts a waterproof structure system to prevent rainwater from entering the interior of the decorative layer as much as possible, so as to cause corrosion to the internal structure of the decorative layer; the 600 mm wide panel on the top of the canopy is set in a shape similar to a gutter, which is conducive to The rainwater is collected and discharged in time, and the collected rainwater is discharged into the outer gutter of the cloud canopy in the direction of the slope (see Figure 6). The exterior of the gutter is decorated with aluminum veneer, which is integrated with the whole canopy decoration system.

4.3 Waterproof and thermal insulation of façade profiled aluminum plate

For the vaulted outdoor profile aluminum trim coil, it is divided into two parts: insulation and non-insulation according to different positions. Above the elevation of 24 m, it is the outdoor non-insulation part. Except for the waterproof function at the top, other functions are not required; but Below the elevation of 24 m, the profiled aluminum trim coil needs to consider the functions of thermal insulation, waterproofing, sound insulation, noise reduction, etc., and together with the closed circle of the glass curtain wall system between the arches form the facade envelope system of the building. In order to meet the performance requirements of various functions, glass thermal insulation cotton and waterproof membrane are set inside the thermal insulation decoration system, and a noise reduction layer is lined on the back of the profiled aluminum plate (see Figure 7).

5 Other details

5.1 Forming process of profiled aluminum sheet

The thickness of the profiled aluminum plate used in this project is thick, reaching 3 mm, and there are many plate ribs, the forming angle is right angle, and the trough groove is deep, whether it is roll forming process or bending forming process is more difficult. Taking all factors into consideration, the stamping and forming process is finally adopted, which not only has high plate-out efficiency, but also has relatively stable quality.

5.2 Cutting process of profiled aluminum plate

The shape of the arched aluminum trim coil part varies in height and low, so the profiled aluminum plate on the facade needs to be cut with the change of the arc. Due to the complex shape, most aluminum plates need to be beveled, and the angle, direction and position of the bevel are different, which brings new challenges to the detailing and fabrication, and the utilization rate of materials will be greatly reduced. In order to ensure the beautiful appearance of the building and the perfect presentation of the architect's design intention, the drawings of each board are set out in detail by the detailed design, and processed and cut in the factory to ensure the quality and appearance of the product.

5.3 Sealing treatment of structural perforations

The main structure is staggered and complex, and there are many connecting rods between the arch truss and the canopy truss structure, which frequently penetrate the profiled aluminum plate from different angles and positions. In order to ensure the waterproof performance of the aluminum plate system, the structural perforated nodes are individually designed and processed according to different situations, fully taking into account the aesthetics, waterproofness and operability (see Figure 8).

6 Conclusion

Guangxi Culture and Art Center comprehensively uses various forms of aluminum alloy materials, including aluminum veneer, aluminum profiled plate, aluminum grille, aluminum composite plate and aluminum profile, etc., which fully outlines the unique shape of the building and presents The perfect effect of the building expresses the architect's design intent. Using the diversity of aluminum alloy decorative panel materials, aluminum decorative panels have been widely used in public buildings, and it is believed that more special-shaped buildings will adopt similar design schemes in the future. The successful implementation of the aluminum decorative panel in the Guangxi Cultural and Art Center project provides a reference sample for the design and construction of other projects in the future.

Mobile:86 17344894490

Email:sales@signialuminium.com

Address:A126 Building 4, No.89 Science Avenue,National HI-Tech Industry Development Zone,Zhengzhou,Henan