- CONTACT EMAIL:

- sales@signialuminium.com

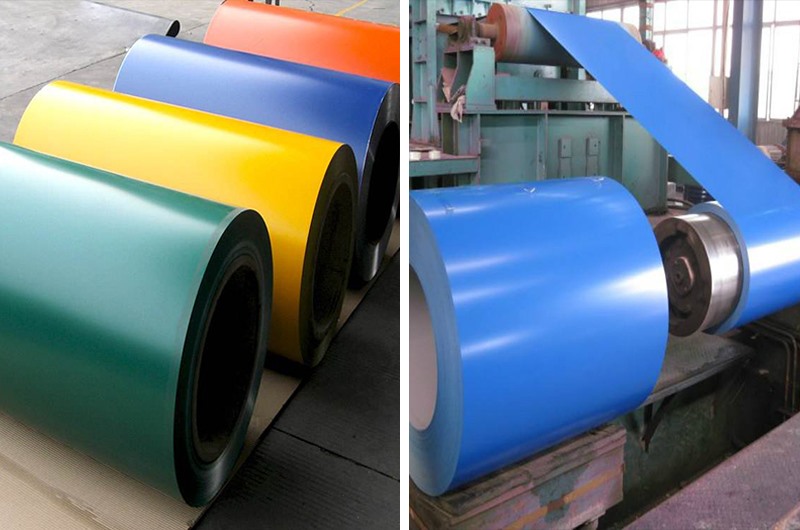

Coated aluminum coil refers to a product with color spraying effect on the surface of aluminum coil, also known as color coated aluminum coil and color aluminum coil. The purpose of coating treatment is to have a beautiful effect in the fields of architecture, decoration and home; Second, the coating process and coating thickness are directly related to the product quality and service life of coated aluminum coil.

Coating technology is a key step in the production of color aluminum coil, which directly affects the quality of the final coating and the durability of the product. Therefore, the coating process is very strict. With the continuous improvement of coating equipment and the development and utilization of new coatings, the production of coated aluminum coils is more mature, and the processing cost is also decreasing. Therefore, coated aluminum coil has obtained rapid development. What is the specific process of coating aluminum coil?

There are 5 steps in the production process of general coil coating, namely coil input, cleaning and chemical treatment, painting, curing and finished product output. The process layout and equipment composition are different in different cases, but the basic parts are the same.

1、 Raw material coil input means that the uncoiler continuously uncoils to ensure the continuous and stable input of the coil into the production line. Some adopt the cross rotating beam type coiler, and some adopt the two sets of alternate uncoilers in front and back. In short, it is for timely coil supply;

Aluminum coil

2、 Surface cleaning and chemical treatment means that the upper and lower surfaces of the aluminum coil must be cleaned and chemically pretreated to ensure that the paint can be firmly attached;

3、 It is painting. One production line has at least two or more roller coating machines to ensure two layers of finishing coat and primer;

4、 It refers to the curing of the paint layer, which means that the tape coil that has just been painted should be fixed before contacting the next roll surface to avoid mutual adhesion and damage. Generally speaking, it contains at least two curing boxes;

5、 It is the output of finished products to ensure that the speed of the production line is synchronized with the transfer of finished products.

Mobile:86 17344894490

Email:sales@signialuminium.com

Address:A126 Building 4, No.89 Science Avenue,National HI-Tech Industry Development Zone,Zhengzhou,Henan