- CONTACT EMAIL:

- sales@signialuminium.com

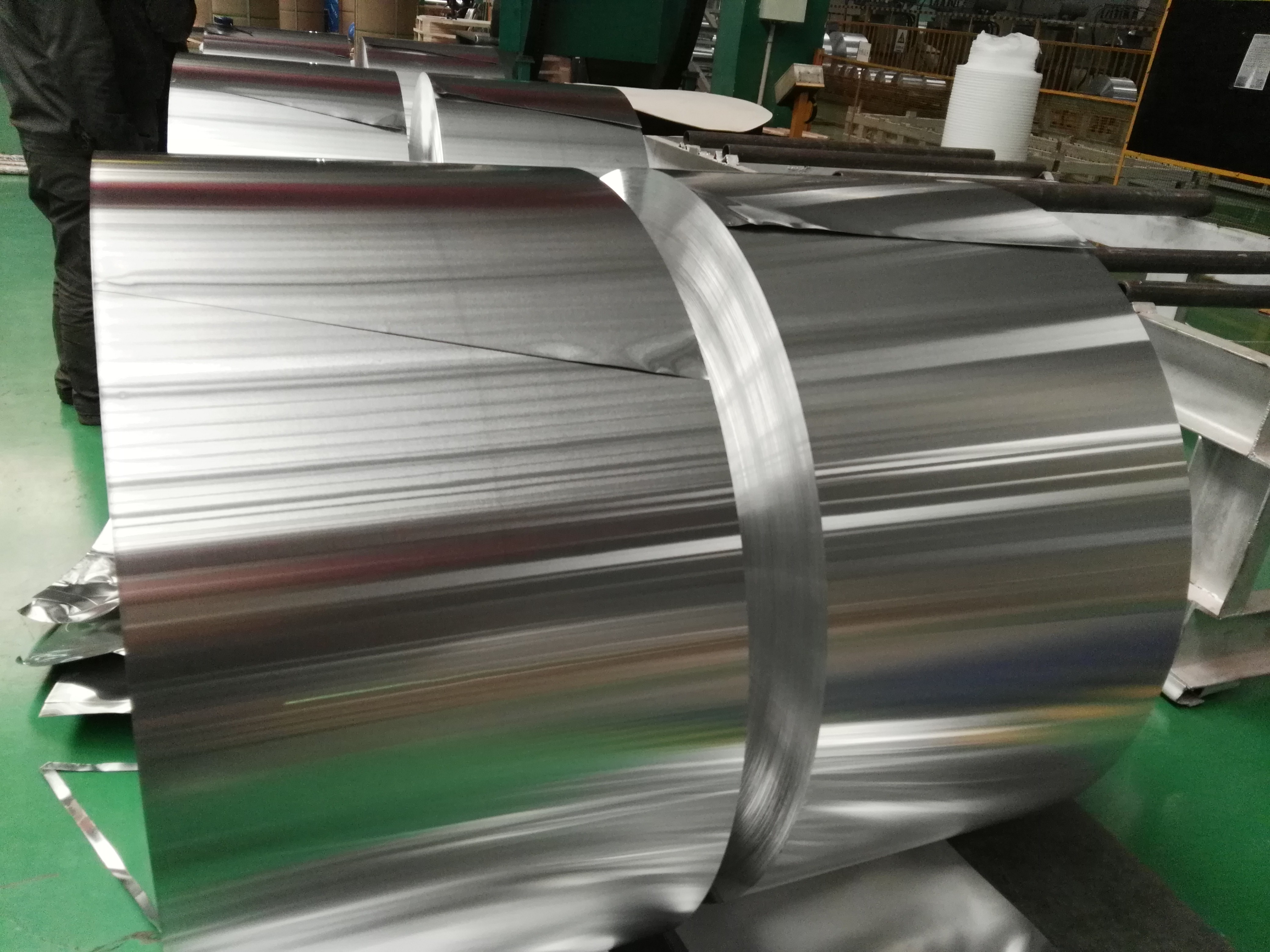

1. The production and processing method of anti-rust alloy aluminium coil is attributed to rolling processing, also known as "calendering" processing. Generally, two methods are used: hot rolling and casting rolling.

(1) The characteristics of hot rolling method: in the process of large plastic deformation, the internal arrangement undergoes repeated recovery and recrystallization, crushing the coarse grains in casting condition and closing the micro-cracks, which makes remarkable improvements in the internal arrangement of billets, the size and shape of grains, the change of defect concentration and other casting defects.

(2) Transforming as-cast arrangement into deformation arrangement greatly improves the processing performance of metals. Especially in deep drawing property, hot rolled material has the advantage that Cast-rolled material can not be compared.

(3) Characteristic of casting-rolling method: The internal arrangement of cast-rolling plate belongs to semi-cast structure, and the orientation of crystal is strong. Compared with hot rolling, it has the characteristics of less investment, low cost and high efficiency.

2. Cold rolled aluminium coil and hot rolled aluminium coil have different uses. Cold rolled aluminium coil is mostly used for dies. Hot rolled aluminium coil is suitable for stamping and drawing. The physical properties of the same material differ greatly due to different manufacturing processes.

3. Antirust alloy aluminium coil can be divided into cold rolling and hot rolling. The primary difference is the difference between anodic oxidation and hot rolling aluminium coil can be anodized.

4. Aluminum processing is also known as plastic forming. According to the stress-strain state of aluminum during deformation, it can be divided into casting, forging, kneading, spinning, drawing, rolling, forming (cold pressing, deep drawing) and other processing methods.

Mobile:86 17344894490

Email:sales@signialuminium.com

Address:A126 Building 4, No.89 Science Avenue,National HI-Tech Industry Development Zone,Zhengzhou,Henan